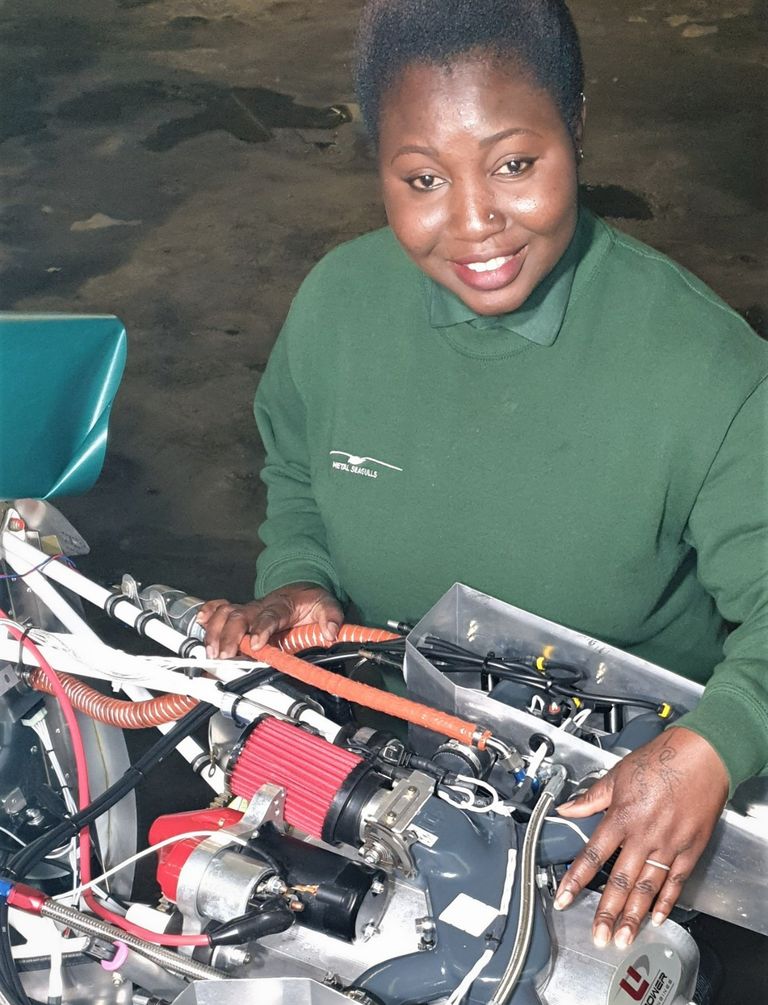

Prof. Patricia Mawuli Porter OBE DL

Patricia, as founding director, is the driving force for developments at Fafali. With a foot in two continents. Patricia has an understanding of aviation as an engineer and pilot which goes beyond exceptional. Patricia has built and maintained aircraft in West Africa and the UK and leads the production team for Fafali Aircraft.

Patricia completed her apprenticeship in Aviation and Technology in Ghana, West Africa, and is both an LAA and BMAA aircraft inspector (and the first black female inspector for either organisation). Patricia has broken many barriers in aviation, and has received many awards and recognitions for her achievements. She is the first woman to be factory trained by ULPower Aero Engines(2017), the first woman factory trained by Rotax Aircraft Engines (2008), and the first civilian woman to obtain a pilots licence in Ghana (2009). She has been recognised for her contributions to the industry by the President of Ghana (2012), and more recently, Patricia was awarded an OBE by Her Majesty the Queen, for her services to Aviation in the UK (2022). More recently Patricia's contributions to engineering have been recognised with a Professor of Practice being awarded by the University of Wales Trinity Saint David, and she was also appointed as a Deputy Lieutenant of Dyfed in 2024. Patricia has flown many humanitarian and surveillance missions, worked on aircraft customisation/ modification/ delivery programmes for air-drops and photo-video missions, and was instrumental in the UK approval of wing structure modifications for the CH750 CRUZER. Patricia ensures that the team stay on track to make Fafali Aircraft DGI (Diverse Geometry Inclusivity) compliant and ensures that the design stays true to its ambitions for ease of production and maintenance.

Patricia works closely with the teams at the University of Wales Trinity Saint David, Pembrokeshire and other Colleges as an inspirational role model for students. She works with apprentices and interns as part of her commitment to training the next generation of engineers and innovators.

Gwenevere Fafali Porter

Gwen is our youngest shareholder, but also a key part of our team. Gwen spoke at the University of Wales Trinity Saint David in 2023, and brings a fresh eye to many aspects of aircraft development. She is the youngest person to have completed the ULPower Factory engine installation course, is growing her TiG Welding skills and is at home with a wide range of CNC machine tools. The factory is her home and locus of learning.

Gwen thinks and works above her age group, and has a natural ability with numbers and chemistry.

She is currently studying subjects normally reserved for tertiary educational institutions and her bright mind brings many outstanding technical solutions to the development.

Gwen is already adept at many aspects of CAD and 3D printing, and is at home at the workbench as she is in the cockpit of one of our development aircraft.

Gwen has had positive inputs to the software development side of Fafali and will certainly be adding much more in years to come.

Gwen, and her generation, deserve better aircraft to meet the demands of a changing world. What better way to ensure success than to include her in the design and development team.

Philip Cronje

Phil is our African office lead, and a member of the design spec team. His background in field maintenance and prototype developments, coupled with his infectious passion for nex-gen aviation helps to drive the Fafali forwards in a practical manner.

With a solid background in engineering as a product development engineer, Phil found my passion in aviation with IFR and twin engine training – as well as test pilot approvals. Phil is qualified across a wide range of aviation brands, including ULPower, Jabiru S.A., and Rotax iRMT (Heavy). PHil has worked extensively in in prototype development and one-off projects with a range of airframe OEMs and homebuilders around the world. As a ‘Factory Approved Maintenance technician’ for several OEMs, Phil travels many thousands of miles each year to troubleshoot and resolve issues based on his extensive field experience. (including Ghana, CAR, Kenya, Zambia, Mozambique, Namibia, Botswana, SA, Lesotho, Panama, China…).

Phil speaks both English and Afrikaans and gets by in French on a regular basis! Regularly working in remote stations for aircraft maintenance and hands-on training of field technicians, Phil has a rather exceptional knowledge of the challenges in relation to repair schedules - with limited tooling and resources.

Phil has been working with members of the team for the past 9 years, and shares the team passion for an easy to maintain and operate aircraft with the robustness needed for extended operational cycles in the challenging environments of Africa.

Phil is based in South Africa, and travels throughout the continent for aircraft commissioning, training and maintenance/repairs.

Layney Lindsay

Layney is our CNC machinist and Mechanical Engineering Degree Apprentice. As a person, engineer and as an apprentice she brings much energy and strength to the team.

Layney specialises in being able to take a drawing concept to a prototype in incredibly short time frames and is equally comfortable machining card, wax, aluminium, PETG, Acrylic, Polycarbonate, wood or foam. Layney enables us to visualise and test components and subassemblies rapidly and reliably.

We can call on her Matlab skills and she also has composite mould making and layup skills that come in handy with aircraft development.

The Design Team

The Fafali Design Team is led by Jonathan Porter, along with aircraft designers and aeronautical engineers in the UK, South Africa and the USA.

Jonathan brings over forty years of hands-on engineering to Fafali. Having worked on engineering solutions for the civilian and military aviation sectors, as well as motor racing, automotive and industrial needs. He has been instrumental in the development of regulations for lighter aviation in Ghana, and has thousands of hours flying humanitarian, agricultural and training missions in West Africa, Jonathan has first hand experience of the needs of the nex-gen aviation solutions that are needed.

Jonathan has many thousands of hours as a flying instructor/examiner and surveillance pilot - and understands the needs for a robust and comfortable aircraft first-hand.

The Design Team working with Jonathan has been hand picked for their experience and competence. The team includes expertise in UK BMAA/LAA regulatory and inspection requirements as well as experience in LSA design and custom mission aviation. Each Team member brings aspects to the development of Fafali from an engineering, electronics, software, operations and maintenance experience. The Team has access to the latest software and state of the art rapid prototyping/production equipment (4- and 5-axis CNC machining, composite shops, sheet metal shops, electronics labs and collaboration with world renowned University staff and facilities).

Members of the team have worked together for many years in difference capacities and share a common passion for nex-gen, powerplant and energy source agnostic aviation.